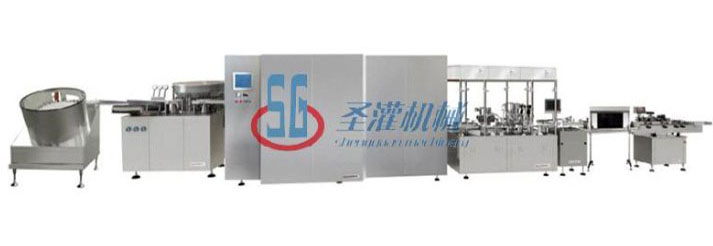

The production line is mainly composed of automatic bottle control machine, ultrasonic bottle washing machine, tunnel dryer, aseptic liquid filling machine sealing machine, labeling machine and so on. It can automatically complete the action of bottle, bottle washing, drying, filling, sealing and labeling of eye drops of eye drops. The design is reasonable and the operation is stable. The

line is a new generation product on the basis of the original connection line. The engineering technicians of our company are combining the leading technology at present, and their structure design is more reasonable and practical, and will be G The general requirements of MP for pharmaceutical equipment are integrated into the design of equipment, so that it is easy to clean, eliminate pollution and provide pharmaceutical products with qualified pharmaceutical products.

Features:

features: the appearance material is stainless steel subsand light treatment or surface sub light treatment, neat appearance and neat without dead angle easy to clean, in line with the GMP specification, can adapt to multi specification production.

features: no leakage, no bubbles, no splash.

operating characteristics: stable operation, small noise, accurate filling, less energy consumption, high quality of finished product characteristics:

the entire production line can be single control and interlocking control. The washing machine is made up of three water and three gas to ensure the bottle washing effect. The tunnel oven temperature ensures that the bottle is dry, and the filling part is filled with ceramic pump to ensure that the liquid is free from contamination. On the whole machine platform, the German imported oil free bearings are imported, the upper cover of the upper cover is adsorbed by the vacuum manipulator. The sealing effect of the

screwing machine is good, and the pneumatic marking machine of the labeling machine ensures the production speed. It fully meets the requirements of GMP.

Technical parameters:

production speed: 30-60 bottles / 70-120 bottles /

applicable specifications: 5-30ml

power supply: 380V/50Hz

total power: 37KW

water use: total length of 0.3-0.8 /h

production line: 12m